Sealing Technology

Hermetic Seals

Hermetic seals are used as a feedthrough and also used to protect the internal electronic components from environmental influences such as temperature, humidity, and pressure. Koto's hermetically sealed packages achieve high hermeticity by sealing glass or ceramics to metal, and electrical current and signals are extracted from the sealed space. With more than half a century-long experience in designing, developing, and manufacturing hermetic seals, we have a large assortment of products; from a few millimeters to over 100 millimeters in diameter.

Glass to Metal Seal

Koto offers both matched seals and compression seals.

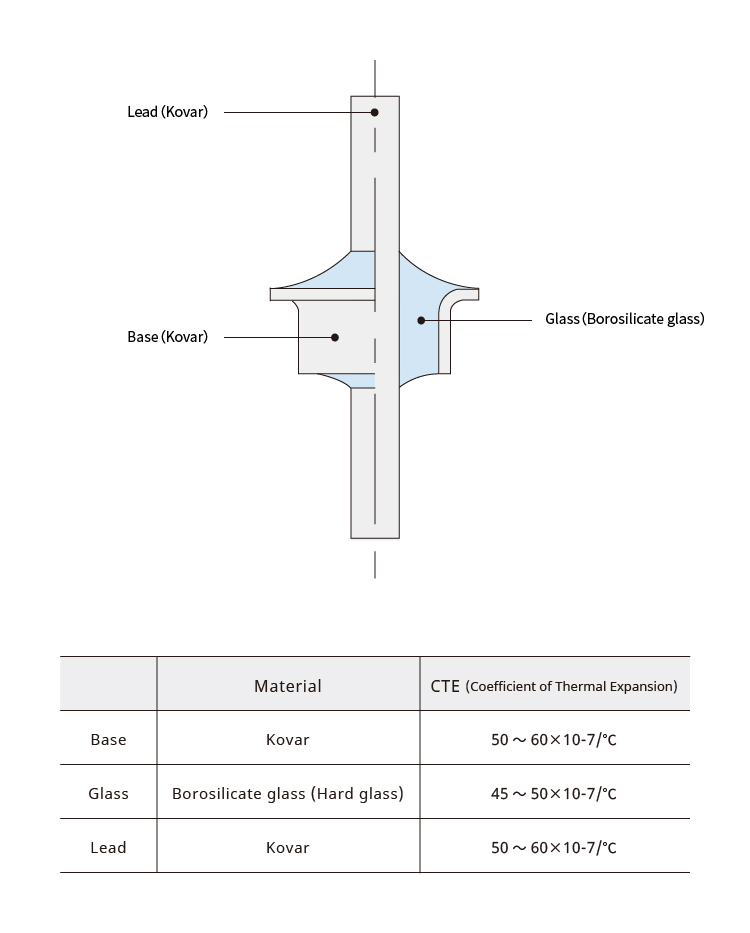

①Matched Seals

Combination of glass and metal that have almost the same thermal expansion coefficient in the glass transition temperature to room temperature. In this method, an oxide film is forcibly formed on the metal surface, and the oxide film acts as an adhesive to seal the materials. Since the coefficient of thermal expansion of metal and glass is almost the same in a wide temperature range, constraints on the shape of the product can be reduced, thereby enabling relatively free design.

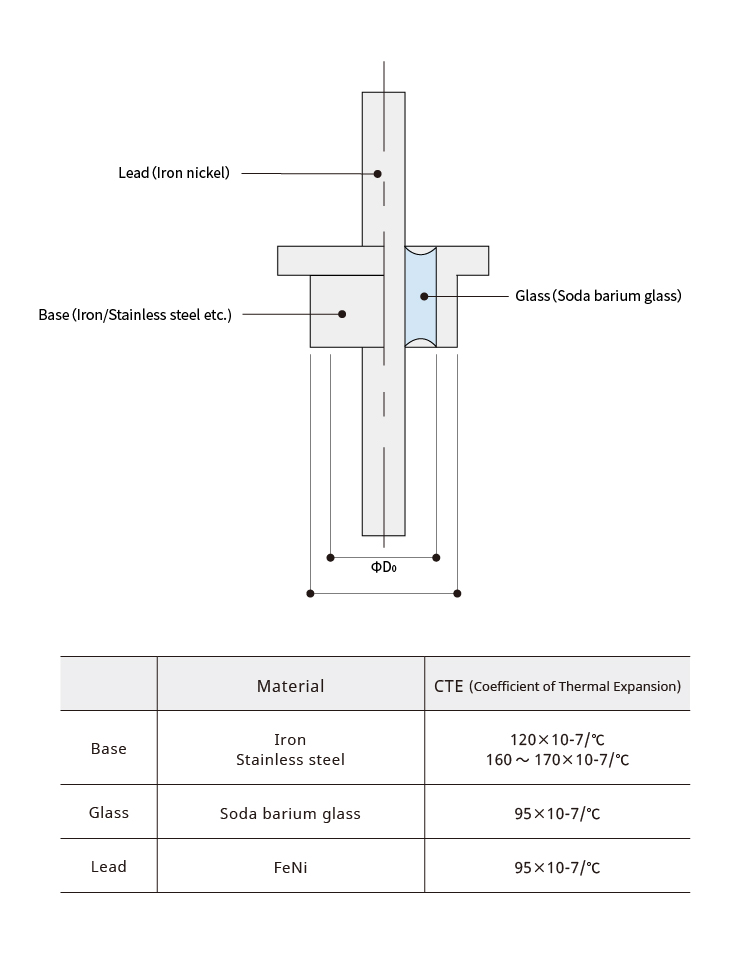

②Compression Seals

The external cylindrical metal part with a higher coefficient of thermal expansion than that of the glass or pin material is used to apply compressive stress on the glass and thereby maintain hermeticity. This method has more constraints on the shape of the product than the matched seals method does; however, the designed pressure can be sustained to maintain hermeticity even when mechanical stress is placed or temperature changes sharply.

Theoretically, the inside and outside diameters need to be φD1/φD0 > 1.3 to maintain hermeticity.

Features of Glass to Metal Seal

| High hermeticity | The hermeticity of our hermetic seals is guaranteed by the He leak test: the hermeticity of 1x10-9Pa·m3/s or less is secured at a normal temperature and under a non-load environment. |

|---|---|

| Excellent electric insulation | The insulation resistance of over 100MΩ at 100V DC in the standard condition is secured. |

| High-pressure resistance | Our hermetic seals can be designed to withstand pressure up to 300 MPa. |

| Customization | We manufacture hermetic seals of various shapes and materials with high technology accumulated through long experience. Please feel free to contact us for your requirements. |

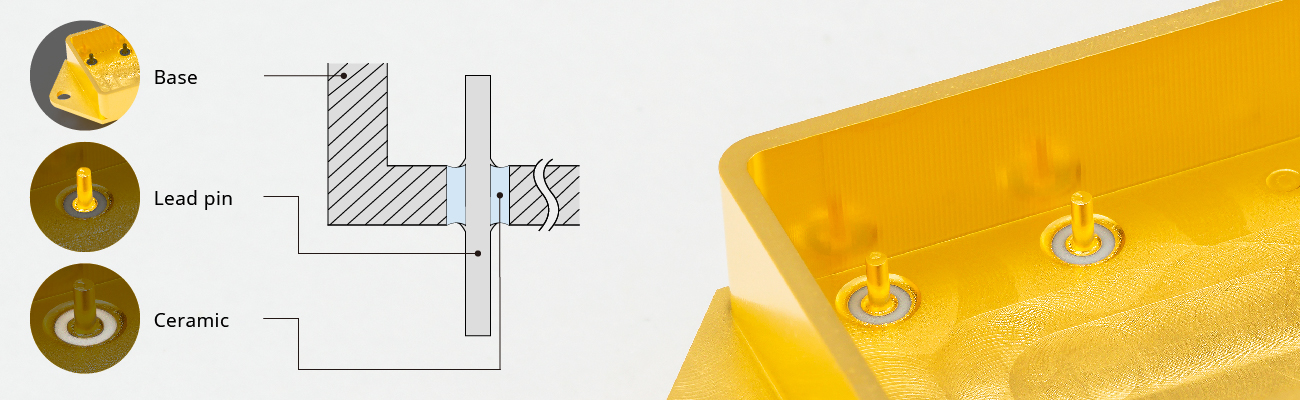

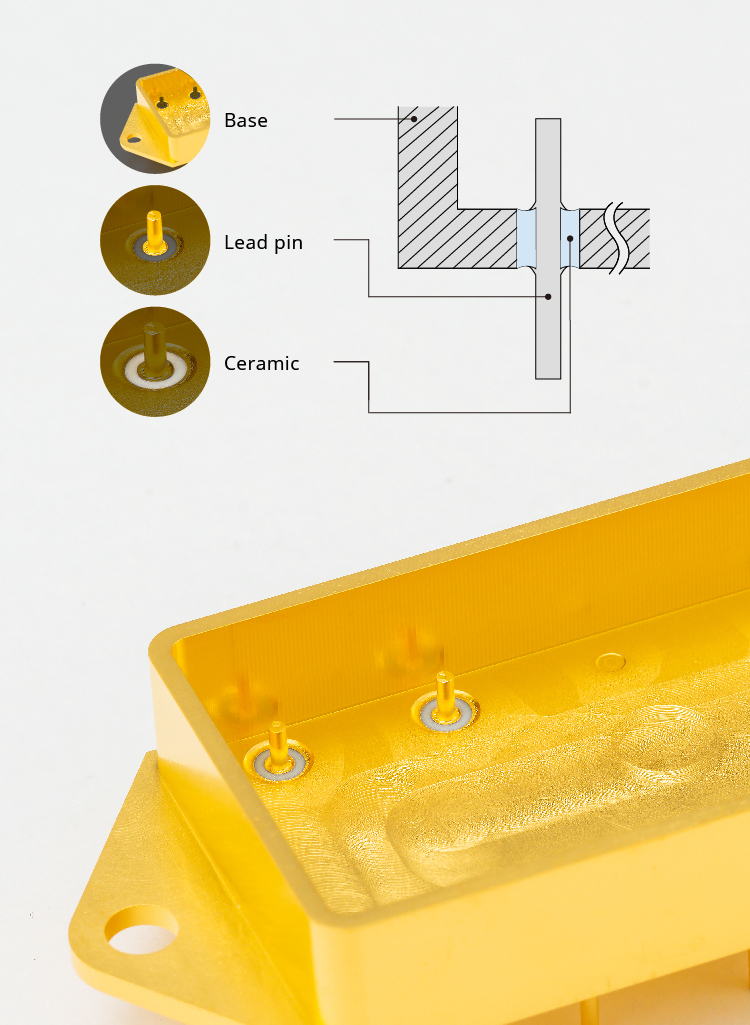

Ceramic to Metal Seal

Our ceramic-to-metal hermetic seals have some advantages over glass-to-metal seals: they have less high-frequency loss, better insulation at high temperatures, higher mechanical strength, and are stronger against thermal shock. Our ceramic-to-metal hermetic seals use alumina (Al2O3) as insulation material. Our quality products are well accepted by the defense and aerospace industries for use in extreme environments where high reliability is required.

Since alumina ceramics basically cannot be bonded directly to metal, a high-melting-point metal (Mo-Mn, tungsten (W), etc.) layer is metalized on the bonding surface of the alumina ceramics; and in addition, nickel is plated on top of it to prevent the oxidation. These processes allow brazing ceramic to metal.

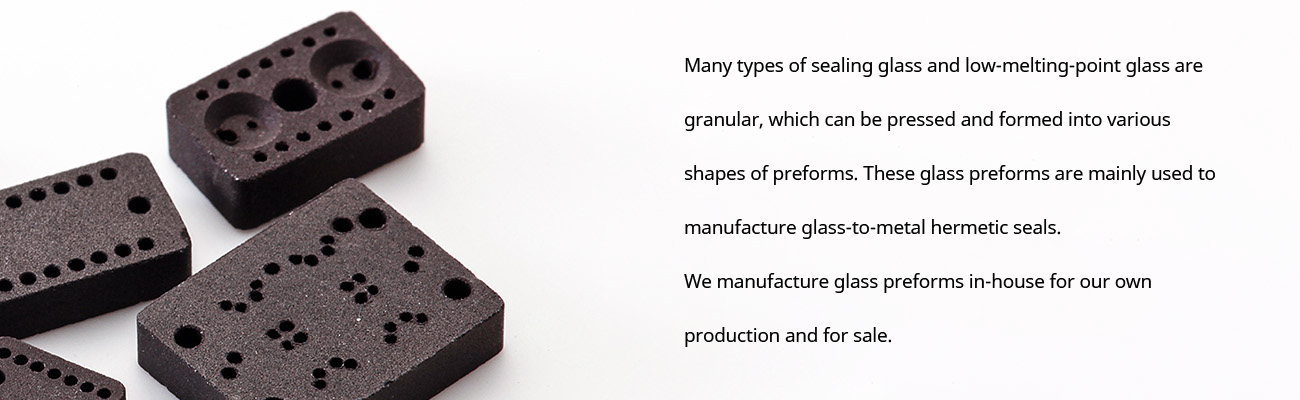

Glass Preform

Features

We can offer quality preforms in various shapes to satisfy customers demands. They are highly accurate parts by strict process control (weight and shape control).

Outline of the Manufacturing Method

Glass preforms are made by pressing granular glass powder with automatic press machine to form various shapes. Then the glass preforms are passed through the furnace, and this process is carried out in two stages. First, the preforms are heated to volatilize the binder. Second, the preforms are further heated to soften the boundaries of each glass particle and bond them with each other. The preforms solidify after cooling, and they considerably contract after going through the whole process and are made to be a final shape.

Surface Treatment (Plating)

The typical materials of our hermetic seals are steel and iron-nickel alloy. Other than corrosion resistance, functional characteristics including bonding and soldering compatibilities can be added upon a customer's request. To ensure these characteristics, the parts need to be plated after being sealed with glass.

Click here for inquiries about each department and product